![]()

![]()

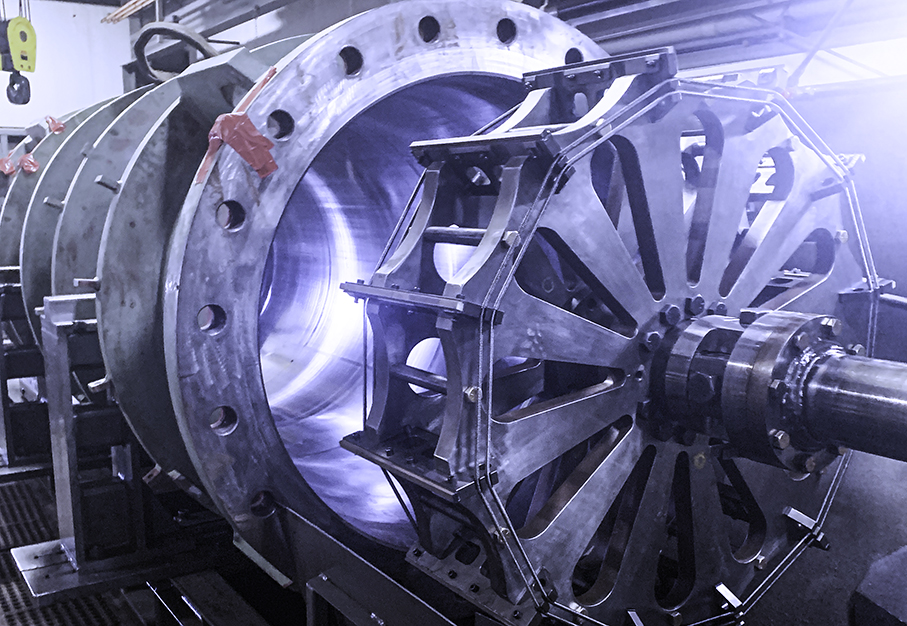

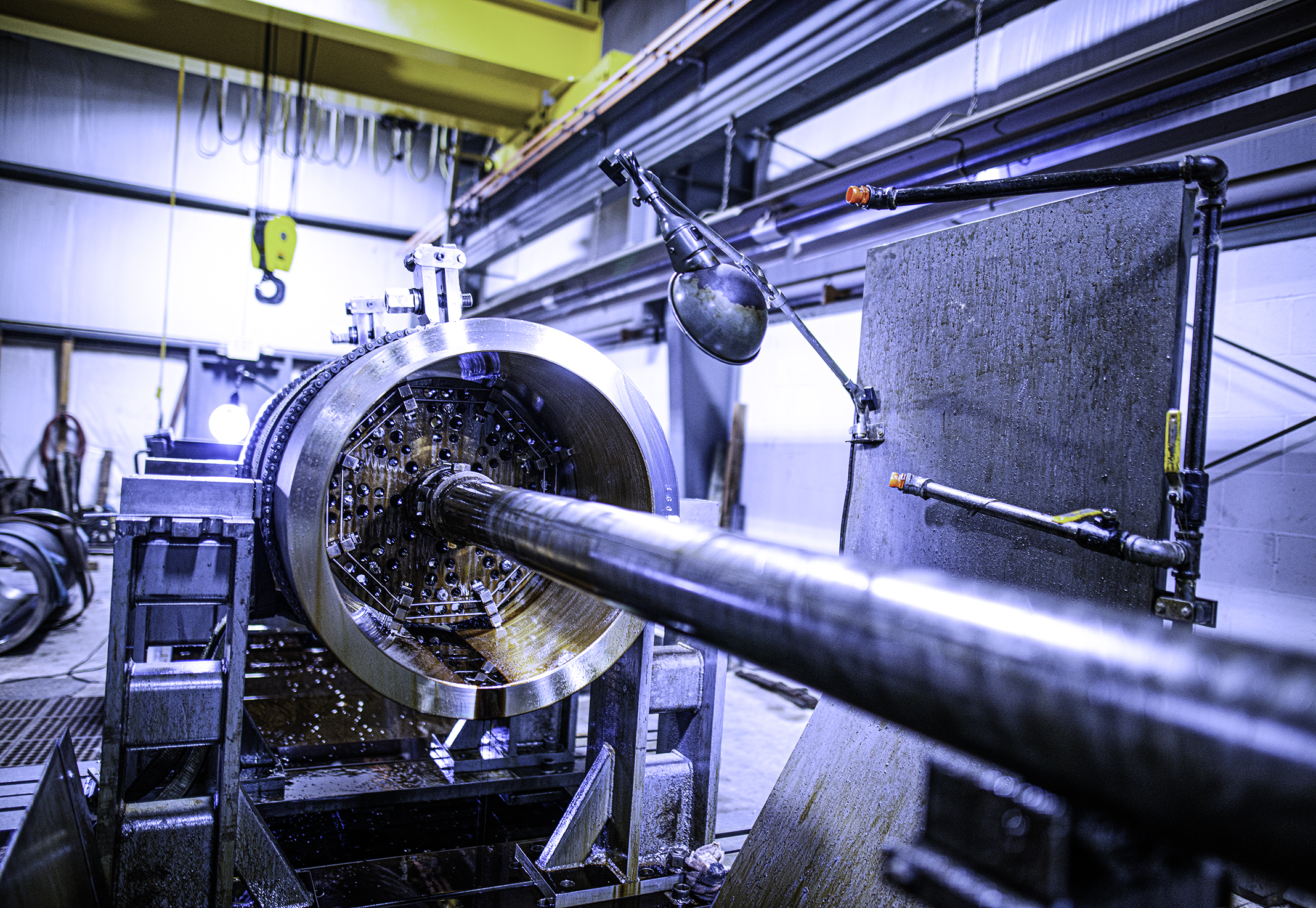

Honing is a metal finishing process similar to fine grinding, which is used to create the optimal surface finish in a hydraulic cylinder tube. It is a simple process and a relatively small portion of the total cost of a cylinder repair.

The honing range is 1.250” ID through 50” ID with a maximum of 65′.

A properly honed tube is the basis for a superb seal, smooth operation, and extended seal life for any hydraulic cylinder. Leaks are the most widely cited repair indicators that will prompt a cylinder repair. When leaks are present, contaminants could enter the system. Contaminants can create scratches, low spots and other irregularities in the cylinder tube wall. These irregularities accelerate seal wear and eventually cause internal leaks. Internal leakage is a silent killer that decreases performance. Deglazing is another reason to hone a cylinder before installing new seals. Deglazing will in effect restore the original crosshatch finish that will improve lubrication, minimize wear and offer smoother operation. Honing can also be considered an inspection tool. After a light hone, surface imperfections may be revealed that could indicate a more severe condition.

Every time a cylinder is resealed, light honing should be performed as part of a thorough repair. It is widely accepted that honing when resealing will save you time and money when you consider the costs of more frequent rebuilds, shortened seal life, and lost time. Honing will renew the bore finish and provide a true bore that is necessary to achieve maximum life, peak performance, and reduced downtime.

In some instances, cylinder damage is too severe and a light hone will not be sufficient. In such cases, the hydraulic repair specialists at Complete Hydraulic Component Service can offer several options for a sound repair.

Address: 10955 Industrial Pkwy Bolivar, OH 44612

Local: 330-874-1003

Phone: 800-837-6299

Fax: 330-874-1103

Product Support Manager

330-236-6971

330-874-1003