![]()

![]()

Do not pre-fill fuel filters. Instead, prime the fuel system per the manufacturer’s suggested procedure. Pre-filling the filters with unfiltered fuel can cause premature fuel system wear or failure.

Best Practices Use only:

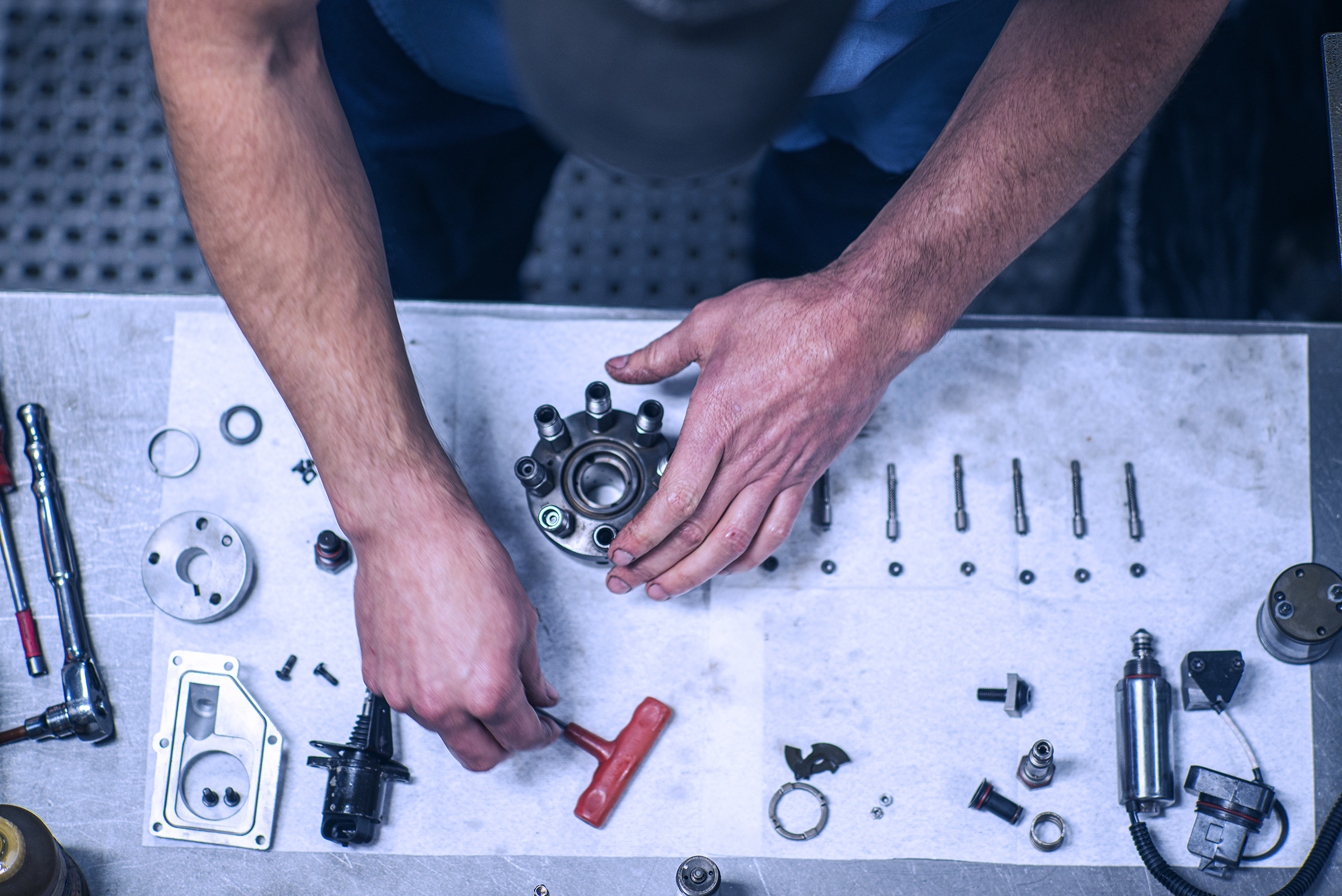

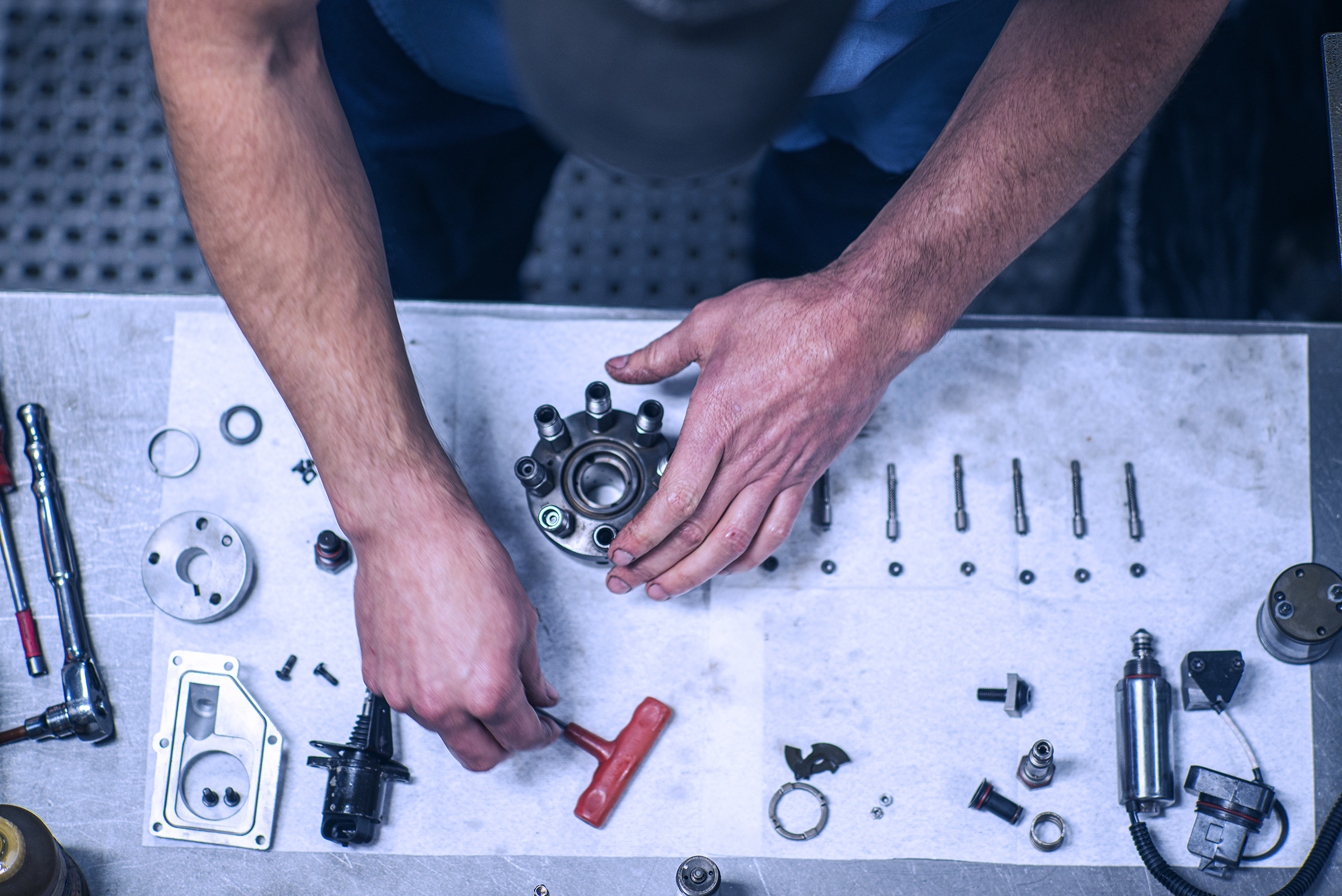

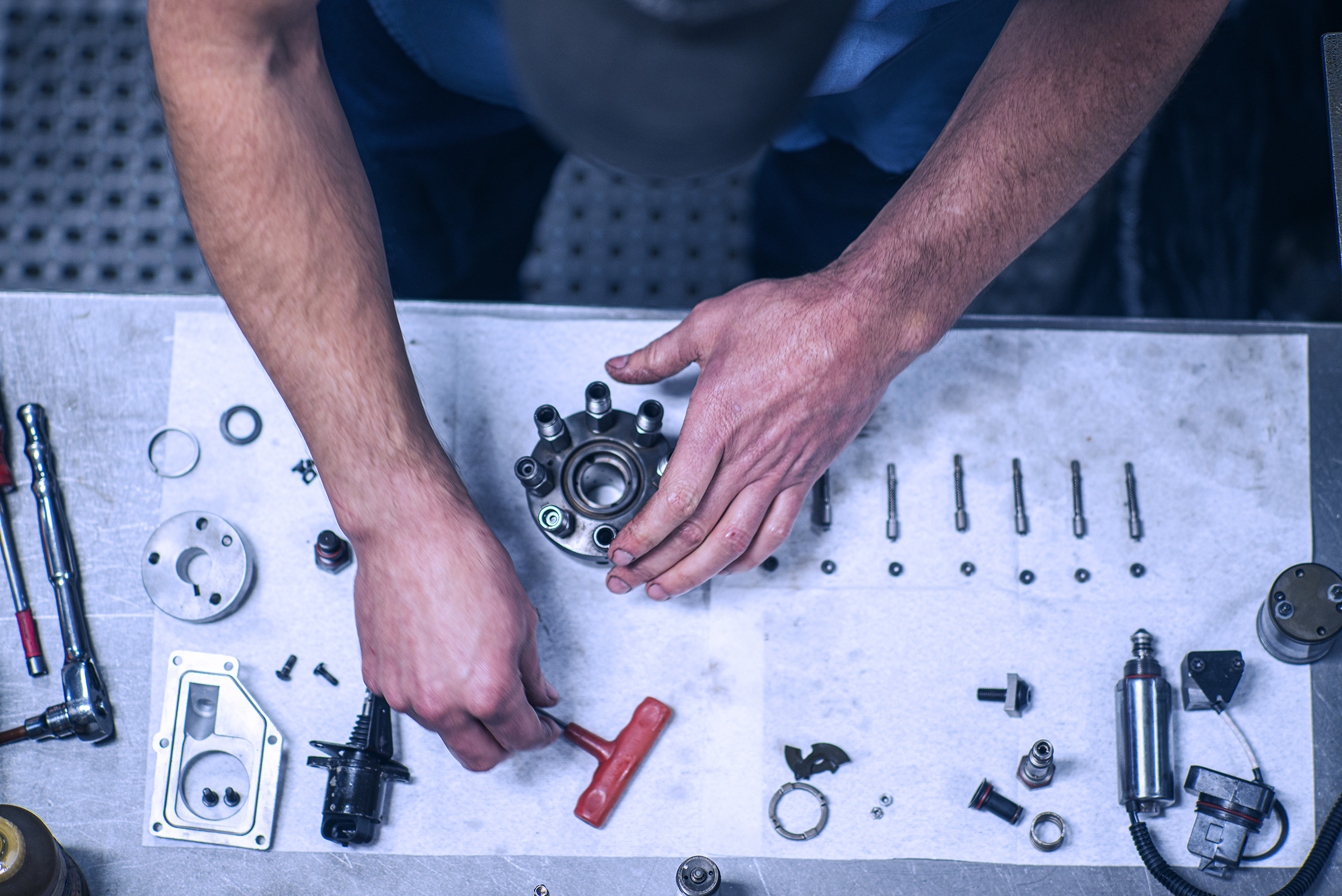

It is critical to degrease the drive shaft or cam shaft as well as the gear or hub before installation. We recommend Electrical Contact Cleaner. Failure to do so can cause the shaft to slip on the gear or in the hub. This can delay timing and cause white smoke, poor run ability, and/or no-start.

Some diesel engines require trim codes that affect the fuel injectors’ timing and fuel delivery throughout the electronic control module (ECM). To get maximum benefit from these types of injectors, you must upload the trim file to the ECM when installing the injector. Failure to do so may result in poor engine performance, rough idle, poor fuel economy, increased emissions, and could result in engine damage.

Turbocharger Leaks can occur when the engine is running at idle. During idle, the lower pressure within the housing can lead to a vacuum causing the oil to leak into the turbine housing. Once the engine starts to run at normal speeds, the pressures are restored and leaks will stop.

Cause: Overspeed, operated outside of design limits

Solution: Check wastegate adjustment

Cause: Excessive exhaust gas temperatures

Solution: Verify fuel settings, look for CAC or manifold leaks, or plugged diesel particulate filter

Cause: Foreign object damage

Solution: Identify the source before fitting a replacement turbocharger

Cause: Inadequate lubrication

Solution: Identify source of insufficient lube, hard contaminants, or fuel dilution

The diesel particulate filter (DPF) is designed to remove particulate matter from the exhaust gas of a diesel engine. Over time, soot will simply continue to build up. While most vehicles have active on-board regeneration processes, these are not 100% effective and over time you may notice the requirement for active or passive regens becoming more frequent. This is a sure sign that it’s time to service your DPF.